Green Circle Growers continually works to improve and

refine the production environment for the orchids in its “Just Add Ice Orchids”

program.

By David Kuack

Green Circle Growers in Oberlin, Ohio, is serious about

producing orchids. It grows 6.5 million phalaenopsis orchids annually in 25

acres of Venlo-style glass greenhouses built specifically for orchid

production.

|

Green Circle Growers’ goal is to produce the most uniform,

highest quality orchids.

|

“We have a high efficiency production system,” said

grower manager Frank Paul. “Everything is standardized. Everything follows a

certain path through our facility.”

Paul said orchids are very manipulative. The greenhouses

are divided into vegetative areas and generative areas. All of the vegetative

areas are at 83ºF

and 65 percent relative humidity. The greenhouses are equipped with a high

pressure fog system for humidity control and also receive supplemental carbon

dioxide.

“Throughout the different vegetative stages of orchid

production the light levels are slowly increased, but the temperature and

humidity remain fairly similar,” he said. “The young plant stage is an average

26 weeks. After the young plant stage, the mature plants in 5-inch pots remain

in a vegetative stage for about 24 weeks before being moved into a cooling

stage.

“Only when the plants are large enough to produce good

quality flower spikes are they moved into the cooling stage. During the cooling

stage, the temperatures are lowered to an average of 70ºF along with an

increase in light levels that initiates the flower spikes. From flower

initiation to shipping is 19 weeks.”

In order to produce plants as uniform as possible, a set

of grading steps was implemented. A camera is used for objective grade

determination.

“Whatever plants are not up to size receive a longer

period of time in the vegetative stage,” Paul said. “Once plants reach the size

that is necessary to produce good quality flower spikes they are moved to the

generative or cooling stage. Our goal is to make the output as uniform as

possible at the highest possible quality.”

Creating the

“perfect” environment

Paul said being able to grow a quality orchid comes down

to the ability to modify the climate conditions to create the perfect growth

environment.

“It is very focused on climate control and climate

control software,” he said. “The first 26 weeks in the young plant stage is by

far the most critical stage. The most important thing is to maintain a stable

growth speed along the way. Disturbances in the growing environment at this

stage can result in a significantly higher percentage of disease and losses.

Those problems can start to a small extent in the young plant stage. Typically

the chances for problems increase once the plants move to the mature vegetative

stage. The problems can be major depending on the level of disturbance

experienced by the plants. That’s why it is so important to keep things stable

at all times. Disturbances include fluctuations in temperature, moisture

levels, soluble salts and pH.”

Grower manager Frank Paul said being able

to grow a quality orchid comes down to the

ability to modify the climate conditions to

create the perfect growth environment.

The greenhouses are equipped with several different

curtains, including indoor and outdoor shade curtains. The outside curtains

help keep the heat out during the summer.

One indoor curtain is primarily for energy savings. The

houses also are equipped with Harmony light diffusion/energy saving curtains.

This white polyester screen brings more light to the plants from all directions

helping to stimulate growth. At night it acts as heat retention curtain.

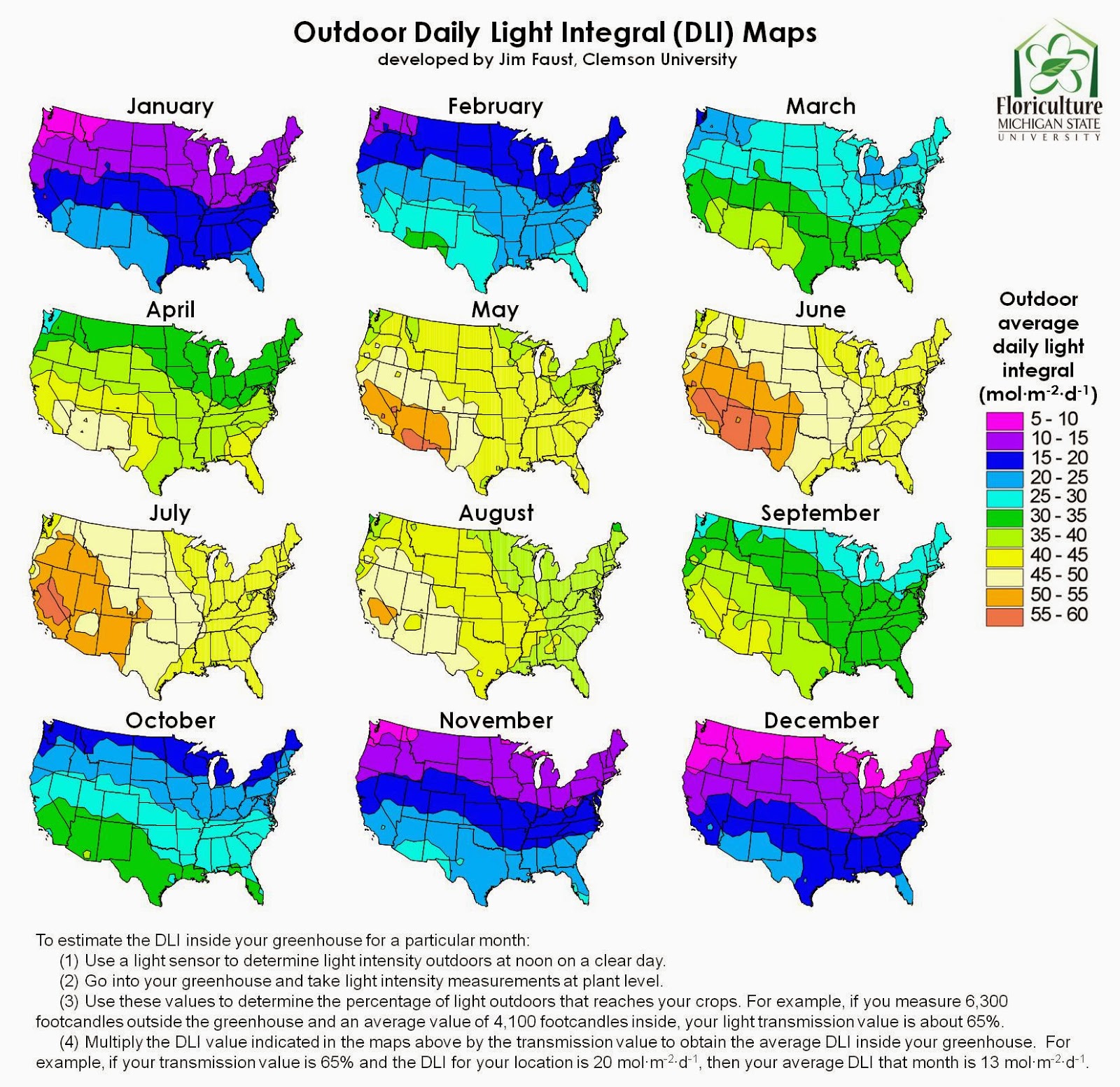

“Orchids are natural shade plants,” Paul said. “They use

fairly low light levels. They don’t like direct sunlight at all so that is why

we are using the Harmony curtains during the day to diffuse the light.”

All of the greenhouses are equipped with high pressure

sodium lamps. In the generative stage areas of the greenhouses the plants need

higher light levels. The greenhouse curtains are open several hours during the

day in those houses. In the vegetative stage greenhouses the Harmony curtains are usually closed 99 percent of the time.

The HID lamps are used primarily during the winter.

“Phalaenopsis are not daylight sensitive, but we try to

maintain a 14-hour day all of the time,” Paul said. “The lamps help to maintain

stable growth at all times. We usually start using them during the second half

of August and run them for one to three hours every morning, gradually

increasing the operating time toward the shortest natural day in December.”

Sweating the small

stuff

Paul said the greenhouses are very open and equipped with

open-structured benches which allow for greater airflow.

“In order to maintain 70ºF during the summer three large chillers have been

installed that produce 38ºF

water,” he said. “The water is pumped to climate optimizers which help to cool

down the air during the warmer months. The climate optimizers located under the

benches are used for both heating and cooling. They can switch back and forth.

The optimizers over the top of the benches are used for cooling only. The

optimizers are basically large air conditioning units through which either cold

or hot water is pumped. The cooled or heated air is sucked through a radiator

and blown through tubes which distribute the air.”

Climate optimizers located under the benches are used for

both heating and cooling. The optimizers are like large air

conditioning units through which either cold or hot water

is pumped.

Paul said orchids are very sensitive to high salt levels.

The soluble salts (electrical conductivity) and pH of the water are monitored

daily.

“We do frequent soil and water sample analyses,” he said.

“We have an in-house water lab that does weekly analyses of specific elements

in the water.”

Rain water is the irrigation water source and is treated

with chlorine dioxide.

“Rain water is relatively clean, but it is important to

keep the water pipes and irrigation lines clean,” Paul said. “Irrigation water

is the primary source of spreading infection. Chlorine dioxide helps to

suppress pathogens from spreading.”

The greenhouses were initially equipped with boom

irrigation, but Paul has been looking at potentially installing an overhead

sprinkler system.

“The booms are spray bars that move over the tops of the

plants up to 10 times during an irrigation cycle,” he said. “The overhead sprinkler

system is a permanent irrigation line, which provides a steadier flow of water

falling on the plants. Overhead irrigation is more constant and allows the

water to flow down through the growing medium and along the sides of the pot

for better leaching. The medium for the finished plants is a mixture of bark

chips and sphagnum peat. Foam is added to the medium in the young plant stage

for the first 26 weeks. All of the drain water is collected into ponds and

reused on other plants in our facilities. It is not reused on the orchids.”

Paul said growing issues with orchids are not seasonally

related. Diseases are the biggest challenge.

“Pseudomonas and Fusarium are very common diseases in

orchid production,” he said. “Pseudomonas is a bacterial disease associated

with the foliage. Fusarium is a fungus that attacks the crown of the plant.

Unstable growth makes the plants more susceptible to these diseases. If the

plants are kept wet too long that makes them more susceptible. Phalaenopsis has

to be dried out before going into the night.”

Paul said the best defense against everything for orchids

is maintaining a healthy plant.

“Creating the ideal conditions for a healthy growing

plant is our main focus,” he said. “Once you get away from that, diseases and

insects become more of a problem. It’s all related to keeping the plants

growing healthy and active at a steady pace all of the time.”

Expanding the Just Add Ice program

The main crop in Green Circle Growers’ “Just Add Ice Orchids”

program

is 5-inch phalaenopsis orchids. As the Just Add Ice name implies, consumers are

directed to use three ice cubes per week to water the plants.

The company has expanded the program with mini-orchids,

anthuriums, bonzi, bromeliads and Pachira

aquatica, called the money tree.

“The mini-orchids account for 10-15 percent of our orchid

sales,” said grower manager Frank Paul. “We are looking to grow the

mini-orchids to 30-40 percent of the program’s sales in the next couple years.

The mini-orchids are also phalaenopsis species.”

The mini-orchids follow similar steps to the other

phalaenopsis, but conditions slightly vary. Because the growing medium is

different for the mini-orchids, there are different requirements regarding

fertilization, irrigation and the cooling process for spike initiation.

Paul said the greenhouses being used for orchid

production are also suitable for anthuriums and bromeliads. Although these

tropical plants finish in about the same time (10-11 months) for the mature

plant stage as the phalaenopsis orchids, they do not follow the same production

schedule. He said the greenhouses designated for phalaenopsis are only used for

orchids.

“The anthurium and bromeliad crops could be grown in the

orchid greenhouses,” he said. “However, because each of these crops requires

its own specific climate conditions and its own specific climate conditions and

has a unique production schedule, we dedicate specific greenhouses to one crop

only.”

For more: Green Circle Growers, (440) 775-1411; fpaul@greencirclegrowers.com; http://www.greencirclegrowers.com; http://www.justaddiceorchids.com.

David Kuack is a freelance technical writer in Fort Worth, Texas;

dkuack@gmail.com.

Visit our corporate website at https://hortamericas.com