Greenhouse lettuce can be a successful container or

hydroponic crop for ornamental plant growers looking to give edibles a try.

greenhouse crop may want to try lettuce. Neil Mattson, associate horticulture

professor at Cornell University, said lettuce is a plant with moderate

fertility needs.

fertility needs than a greenhouse tomato crop,”

Mattson said. “Grown as a

container crop, lettuce is relatively similar to petunia. However, lettuce has somewhat

greater calcium needs. Growers can produce a relatively good crop of lettuce in

containers, if they use a complete fertilizer at a moderate strength of 150

parts per million nitrogen.”

to a bedding plant crop. The seed would be planted into a plug tray for three

to four weeks. Transplanting the plugs into larger containers, the crop could

be finished in four to six weeks depending on light and temperature levels.

is directly sown into the growing medium and grown for three to four weeks

until plants reach suitable size.

tipburn

Leaf tipburn is a physiological disorder that can occur

when growing greenhouse lettuce. It can greatly impact the salability of a

crop.

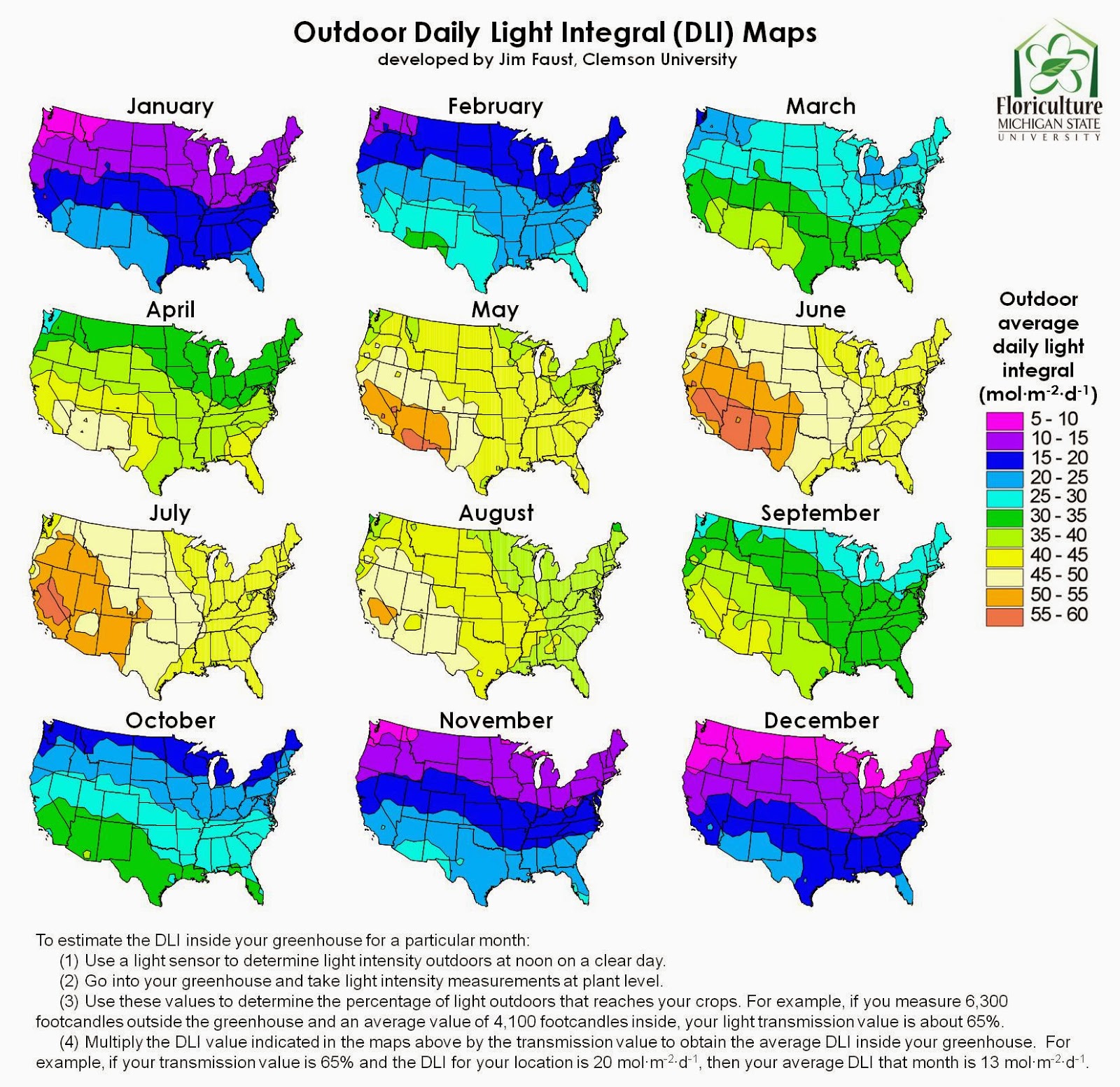

growing too fast under high light,” Mattson said. “For lettuce, the target

daily light integral is 17 moles per square meter per day. The light level should

be lower if there is poor air flow. If the light level goes higher than 17

moles, the rapid growth of young leaves is affected. There may be an inadequate

calcium supply, especially as the lettuce heads begin to mature and close. If

there is not enough air flow and not enough transpiration by the young leaves,

then not enough calcium can reach the leaves through the xylem sap. This can

cause tipburn to occur. It’s a case of pushing the plants too fast.”

|

| Calcium tipburn in lettuce is not a result of a lack of calcium supplied to the plants, but an inability of the plants to transport enough calcium to the young leaves. |

lack of calcium supplied to the plants, but an inability of the plants to

transport enough calcium to the young leaves.

calcium if the growing medium has a lime charge and if the fertilizer water

solution contains more than 50 ppm calcium,” he said. “Many common bedding

plant fertilizers, including 20-20-20, 20-20-20 and 21-5-20, do not contain

calcium. These fertilizers are typically used with tap water sources that

contain moderate alkalinity. In many cases, these tap water sources also

contain sufficient calcium.”

water sources to make sure adequate calcium is being supplied, either from the

water source or added into the fertility program. If calcium needs to be added,

calcium nitrate is most commonly used. However, calcium nitrate is not

compatible with most complete fertilizers.

using a separate stock tank or a separate injector,” Mattson said. “One

strategy is to use a separate injector for the calcium nitrate in a series with

a 20-10-20 fertilizer that is being added with a second injector. Adding 50 ppm

calcium from calcium nitrate should be sufficient.

grower has only one injector is to rotate between two separate stock tanks, one

for calcium nitrate and one for the bedding plant fertilizer. A grower would then

rotate between the two fertilizers. For example, for two days he would use the

20-10-20 fertilizer and on the third day he would use the calcium nitrate

applied at 150 ppm.”

organic fertilizers

Mattson has been able to grow a relatively good crop of

container-grown lettuce using granular organic fertilizers incorporated into

the growing medium.

8-4-4) into the growing medium at a rate of 8 pounds per cubic yard for both

the seed germination and transplant growing mixes,” he said. “That provided

good fertility, but for optimum yields I would also suggest making some liquid

organic fertilizer applications, maybe two to three times a week as the plants

get older.”

temperature-dependent and is broken down by soil microbes. Sustane 8-4-4 has a

45-day release period, but under very warm greenhouse temperatures Mattson has

noticed quicker release rates. He said there are other slow release organic

fertilizers with different release periods. For example, Verdanta EcoVita lists

a 75-100 day release period.

electrical conductivity and pH

One strategy that Mattson recommends growers do periodically

is to monitor the electrical conductivity (EC) and pH levels.

are receiving sufficient fertility,” he said. “If a grower is incorporating a

slow release fertilizer, this is a good indicator of when additional fertilizer

needs to be added. An under-fertilized plant will show yellow lower leaves from

nitrogen deficiency.”

|

| Monitoring electrical conductivity (EC) can help avoid under fertilizing lettuce plants, which show yellow lower leaves caused by nitrogen deficiency. |

nutrient availability. He said lettuce isn’t commonly susceptible to iron

deficiency, but it will start to show up when the pH starts to increase above

6.5-7.

hydroponics,” he said. “A good grower who is producing his crop in a growing

medium in containers will monitor the pH every week or two. The pH may change

over the course of a week by maybe one unit.

the pH every day and make adjustments. Depending on the type of fertilizer and

the quality of the water, the pH in a hydroponic set up could change two units

in a day.”

production

Mattson said light and temperature are going to be the

drivers for how long it takes to finish a lettuce crop. Whether a grower is

producing the crop in containers with growing medium or hydroponically

shouldn’t have any effect on the length of production.

lettuce head. If plants are grown in small containers and spaced pot-to-pot,

the lettuce heads may not reach full size.

developed a hydroponic production model that enables growers to produce a

lettuce crop from seeding to harvest in 35 days if temperature and light

intensity are at optimum levels.

take more than 100 days from seeding to harvest,” Mattson said. “High pressure

sodium lamps would be the best lamps to use if a grower is looking to provide

supplemental light in a greenhouse to increase the daily light integral. For

the Cornell model we adjust the amount of light in the greenhouse based on the

amount of outdoor light. Seventeen moles per square meter per day is the daily

light integral we are aiming for with the model. The optimum temperature for

plant development is about 75ºF

during the day and 65ºF

at night.”

For more: Neil

Mattson, Cornell University, School of Integrative Plant Science; (607)

255-0621; nsm47@cornell.edu.

Worth, Texas; dkuack@gmail.com.

Visit our corporate website at https://hortamericas.com