U.S. researchers are looking at the potential benefits to

the propagation and production of greenhouse ornamental and vegetable crops

using LED lights.

By David Kuack

Although U.S. researchers have started studying the

effects of LED lights on the production of greenhouse ornamental and vegetable

crops, much of the data being used by American growers comes from studies done

in Europe. Purdue University horticulture professor Cary Mitchell said that studies

currently being done in the United States will provide growers with information

that is relevant to their production and climatic conditions.

Mitchell is leading a team of university researchers who

have received a $4.9 million grant, including $2.4 million from USDA, to study

LED lighting for greenhouse applications. Mitchell along with Purdue

horticulture professor Roberto Lopez is working with scientists and engineers at

the University of Arizona, Michigan State University, Rutgers University and

Orbital Technologies Corp. Mitchell is working with graduate student Celina

Gomez to study the impact of LED lights on the propagation and production of

high-wire tomatoes. Lopez and graduate students Christopher

Currey and Michael Ortiz are studying the use of LED lights on bedding plant

cuttings and plugs.

Propagation trials

Due to limited greenhouse research space, Gomez is using

one bench to compare the effect of providing supplemental light from a high

intensity discharge lamp or from LED lights with control plants that receive

only natural daylight. During the first year of the propagation study, Gomez is

conducting an experiment every month. The experiment includes a control group

of tomato seedlings that receive no supplemental light, an overhead HID lamp

that provides the industry standard and overhead LED arrays that provide three

different ratios of red to blue light.

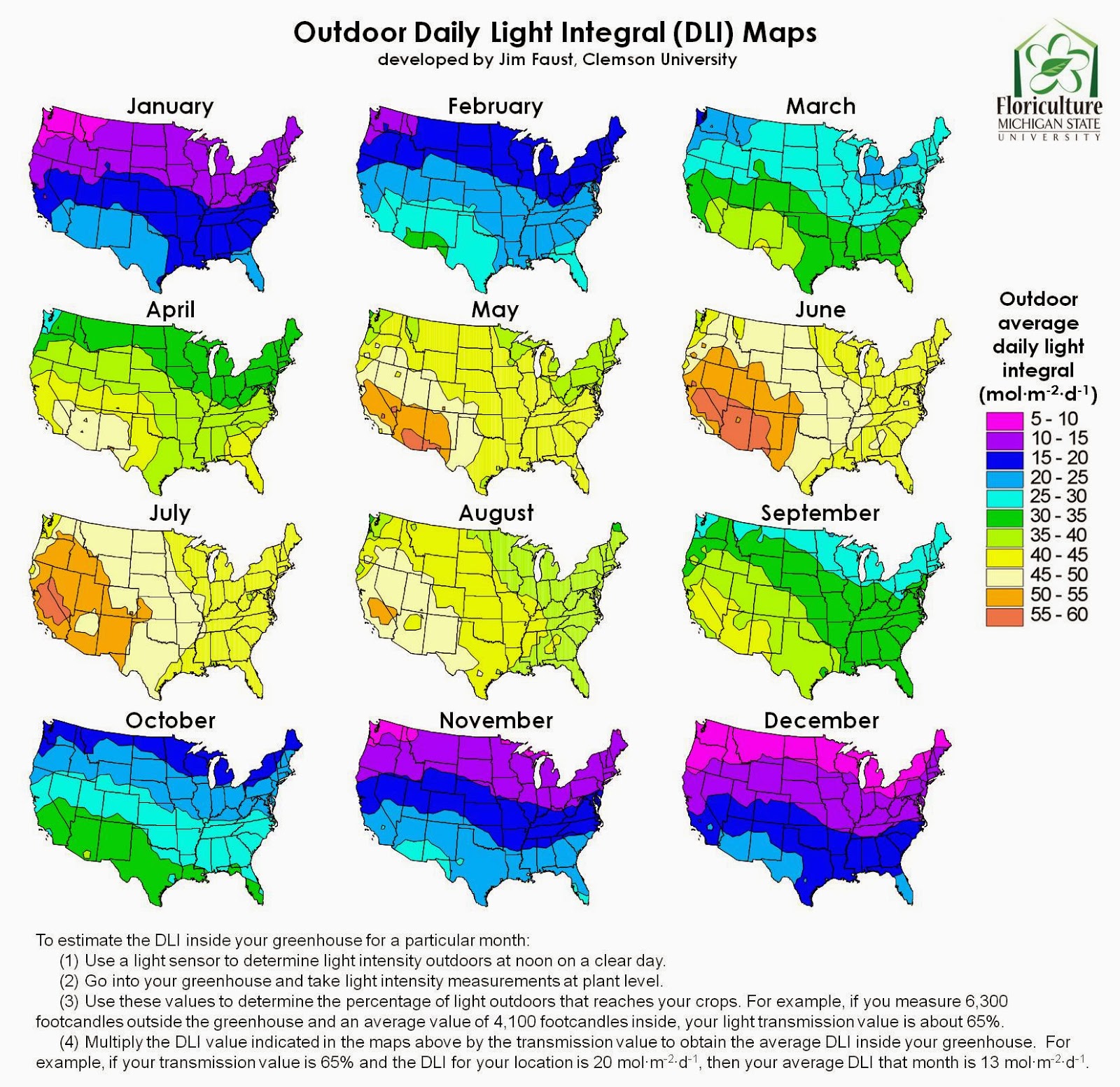

“The propagation experiment is repeated for three weeks

every month,” Mitchell said. “We are measuring the differences in plant growth

from one month to the next. As we enter spring, the ambient light levels are

increasing. Gomez will measure the daily light integral (DLI) that is occurring

and the different red/blue ratios and what the plants prefer and determine what

they need. In addition to the plant metrics being collected, we are also

measuring the amount of electricity used for supplemental lighting.”

After the tomato seedlings reach the stage at which they

would be grafted onto the rootstock, data is being collected including plant

dry weight, height, stem diameter, leaf span and leaf area.

Mitchell said the propagation area that is equipped with

the lights receives 5 moles per square meter per day of supplemental light in

addition to the natural solar daily light integral that varies throughout the

year.

“Since we have only done the experiment a couple of times

so far this year, we’ve yet to see what kind of plant response pattern emerges,”

he said. The supplemental light we are providing now might not be enough light

during the dead of winter. Any benefits of supplemental light that occur during

the winter should disappear as the trials move later into spring. Once we have

obtained a full year profile of seedling response, we will be able to determine

the optimum amount of supplemental light to apply each month.

“One of the best management practices that we hope comes

of this long term study is to determine at what point it is important to use

supplemental lighting, as well as when it is no longer useful to do so.”

For the propagation study the tomato seedlings are

receiving supplemental light for 23 hours a day in order to achieve a daily

light integral of 5 moles per square meter per day.

Tomato seeds are being germinated in a substrate called

steadyGROWpro plugs. Six different tomato varieties are being tested: ‘Success’,

‘Komeett’, ‘Maxifort’, ‘Sheva-sheva’, ‘Liberty’ and ‘Felicity’. Seedlings of ‘Success’

and ‘Komeett’ are used for the production study after being grafted onto ‘Maxifort’.

These varieties were recommended by Marco de Bruin at

Bushel Boy Farms in Owatonna, Minn., because they have

different growth habits.

Production trials

In the production experiments the grafted seedlings are

being transplanted into Coco Agro coir slabs.

“The lighting treatments containing both test cultivars

are blocked into separate half rows in order to determine if there are position

effects within the greenhouse that could affect yields,” Mitchell said.

The plants are being provided with supplemental light

twice a day. He said they are applying a daily light integral of 9 moles per

square meter per day.

“In early March we were lighting for 12 hours per day,”

Mitchell said. “Lighting usually starts well before sunrise and begins again

before the sun goes down.”

The first production study in 2012 began at the end of

January. Mitchell said the tomato plants that had received supplemental light

treatments were already setting fruit in early March.

“The control plants that didn’t receive any supplemental

light were way behind,” he said. “They were barely setting fruit. That’s what

you would expect in a cloudy region like Indiana.”

The first production experiment of 2012 will be

terminated after six months and a second will begin immediately. Mitchell said

the second experiment will be the exact opposite of the first in terms of solar

daily light integral changes.

“We want to see what challenges there are both with the

propagation and the production starting in the summer and going into the winter,”

he said. “If production is started in the greenhouse in July, the plants are

going to be receiving a lot of sunlight. As the photoperiod starts to shorten going

into fall that is when supplemental lighting will be more valuable.

“We are hoping to come up with recommendations for

growers in this region or in any other northern region that has cloudy weather regarding

when is the best time to start lighting their crops. We are also looking at

timing the production so that growers are not competing with home-grown or

field-grown tomatoes. That way the greenhouse growers are not competing with

availability and price for what’s being grown in backyards or in the field.”

Priming the ornamentals

propagation pump

Purdue horticulture professor

Roberto Lopez and graduate students Christopher Currey and Michael Ortiz are

studying the effect of supplemental light on the propagation of ornamental

vegetative cuttings and plugs.

“We’re looking at the top three

flowering crops that are produced from vegetative cuttings, which are

geraniums, petunias and New Guinea impatiens,” Lopez said. Currey and Ortiz are

comparing rooting, dry mass accumulation and other quality parameters under red

and blue LED lights to high pressure sodium lamps. Initial trials with cuttings

have shown that there are not a lot differences in terms of rooting time and

quality between the two light sources. Additionally, preliminary data is

showing no differences in the time to flower or quality of cuttings propagated

under the various LED lights and high pressure sodium lamps for the three

annual crops.

“Initially, the results

are very similar for

both rooted cuttings and finished plants,” Lopez said. “But this is very

preliminary. There were really no differences seen for these three crops. What

we were mainly trying to achieve was a certain daily light integral with both

the high pressure sodium and red and blue LEDs. With the additional trials that

we will be doing we will also be looking to quantify the amount of electricity

used by the high pressure sodium lights and the LEDs.”

Best timing,

amount of light

Lopez said none of the vegetative cuttings received

supplemental light during the first seven days of propagation because that is

when the cuttings are forming callus.

“A grower typically wouldn’t use lights during this

period unless the light level was really low,” he said. “During that period the

grower is trying to baby the cuttings to get them to form callus. If the light

level is too high during this period the cuttings could be stressed. After a

week the cuttings begin to form roots and start to photosynthesize. A grower

can maximize photosynthesis during rooting by increasing the daily light integral.”

Currey’s research and studies

Lopez performed at Michigan State University indicate growers should

provide a daily light integral of between 8-10 moles per square meter

per day to be able to increase rooting and the overall quality of the cutting.

Lopez and Ortiz are also

testing LED lights during plug propagation of celosia, cosmos, impatiens,

geranium, marigold, pansy and petunia.

“One of the biggest challenges with

plug production of annual bedding plants is keeping the plugs compact,” Ortiz

said. “Compact plugs ease transport in boxes and allow for a higher volume of

plugs to be transported at one time. This is definitely something to consider

as fuel prices continue to rise.

“Plugs are often grown in dense

288- or 504-cell trays that promote rapid stem elongation. We are using red and

far red LEDs in end-of-day treatments in an attempt to manipulate the

phytochrome-mediated genes that are responsible for stem elongation under dense

planting conditions. If LEDs can be used to control seedling height, the

industry can decrease its reliance on plant growth regulators.”

Lopez and Ortiz are also

investigating red and blue LEDs as a supplemental lighting source during winter

bedding plant plug production.

“The goal behind this

experiment is to quantify root development under different ratios of red and

blue LED light and high pressure sodium light,” Ortiz said. “We also are also

trying to determine if supplemental light from LEDs can offer more rapid root

development than light from high pressure sodium lamps. This can make a big

impact on energy use in the industry.”

Lopez said producing cuttings is much different than producing

plugs.

“With plugs a grower is starting out with plants that

have roots,” Lopez said. “A grower may end up being able to delay the sowing of

the plugs if he is using lights. We may find that the LEDs might prove to be

even more beneficial with plugs than with cuttings.”

For more: Cary Mitchell, Purdue

University, Department: Horticulture and Landscape Architecture, (765) 494-1347;

cmitchel@purdue.edu.

Roberto Lopez, Purdue University, Department of Horticulture

and Landscape Architecture, (765) 496-3425;

rglopez@purdue.edu;

Visit our corporate website at https://hortamericas.com