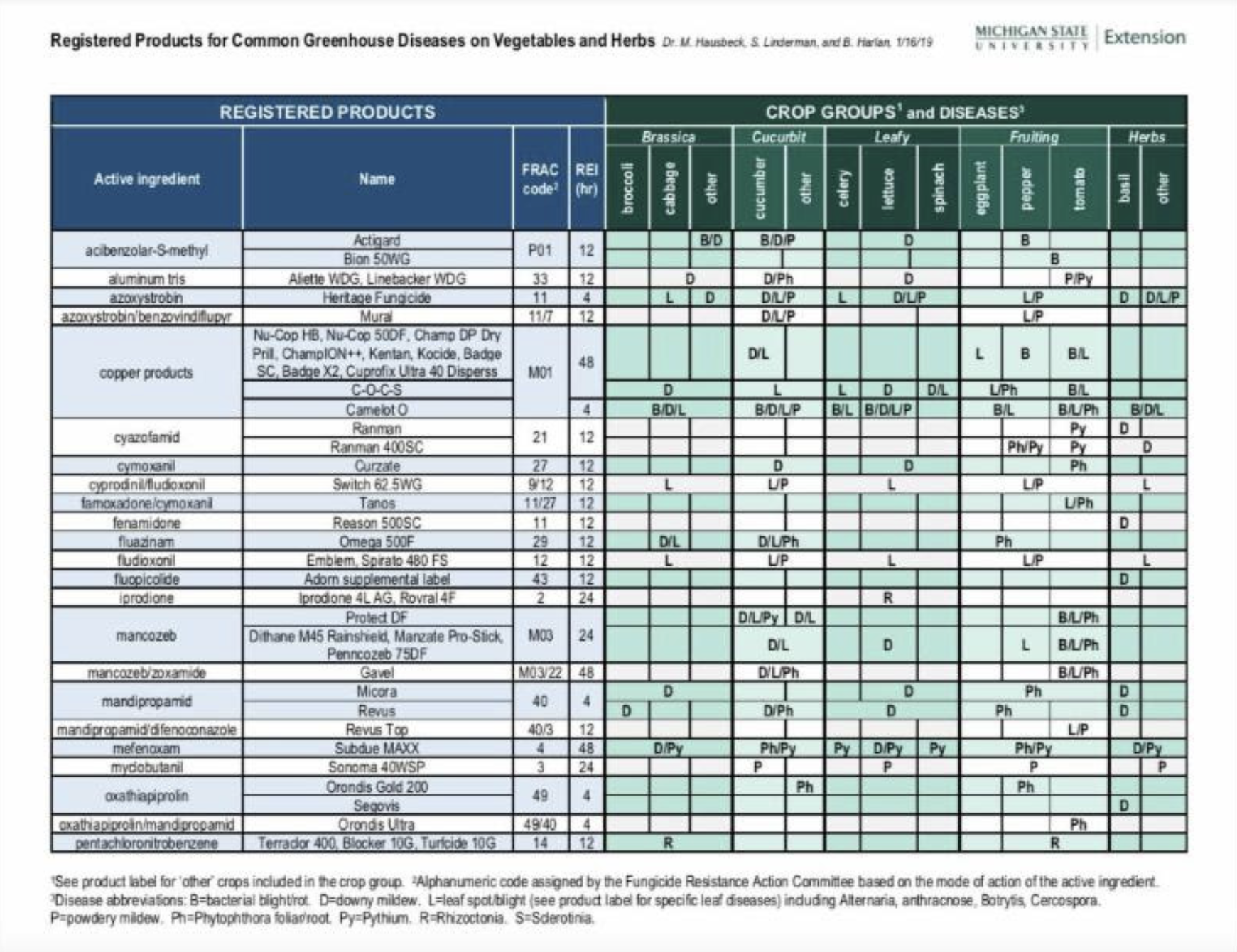

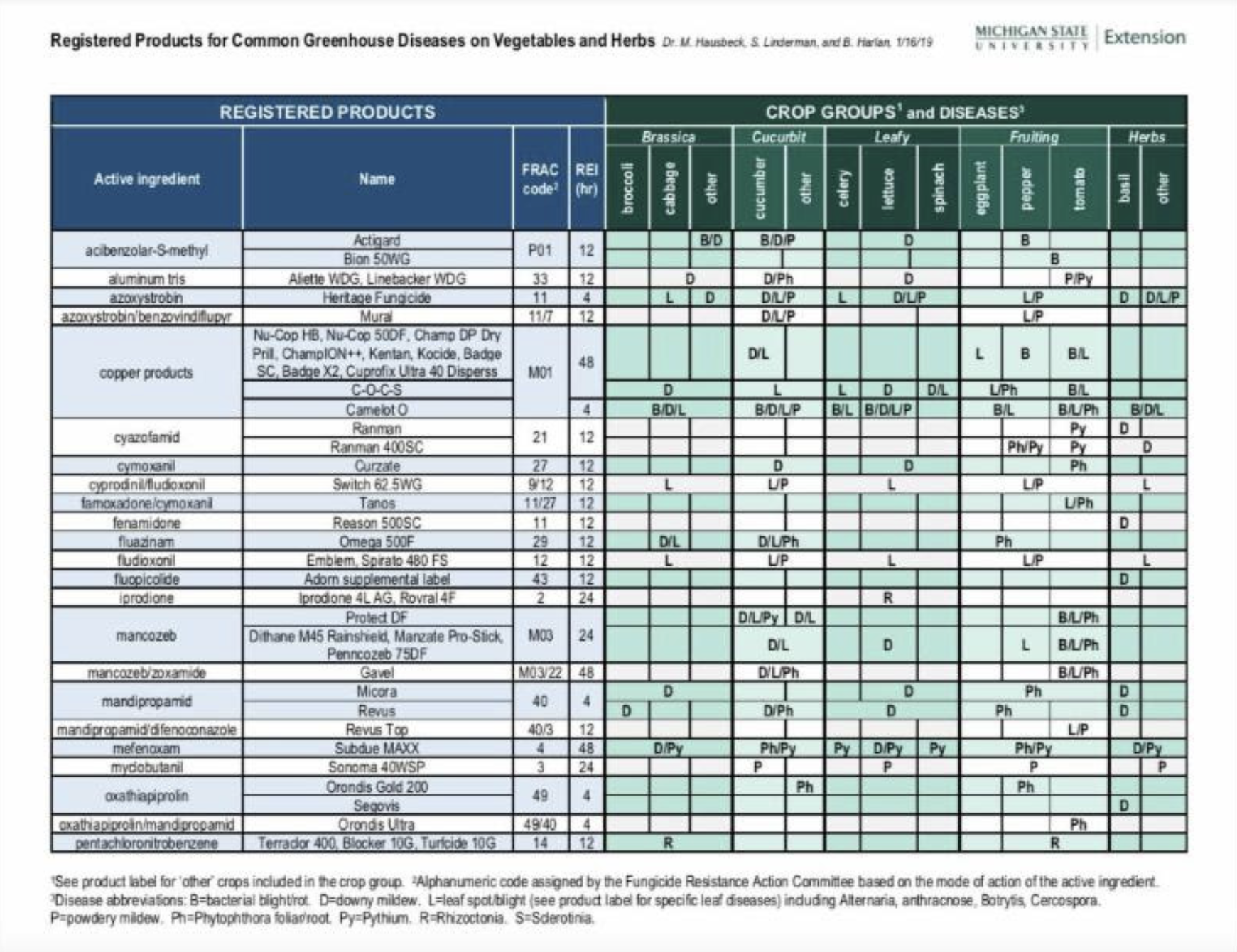

New Greenhouse Disease Management Recommendations for Vegetables and Herbs

Originally written by e-Gro (Heidi Wollaeger) on Jan 24, 2019

Continue reading e-Gro Blog shares new greenhouse disease management recommendations

Originally written by e-Gro (Heidi Wollaeger) on Jan 24, 2019

Continue reading e-Gro Blog shares new greenhouse disease management recommendations

BioBee Biological Systems, headquartered in Sde Eliyaho, Israel, is at the forefront of implementing biologically-based integrated pest management (IPM) solutions in controlled environment agriculture and open-field production systems. BioBee USA, a subsidiary of BioBee, headquartered in Atlanta, Ga., has partnered with horticultural supplier Hort Americas in Bedford, Texas, to work together to educate and provide greenhouse growers, vertical farmers, indoor agriculturalists and hydroponic growers with a wide range of biological control products.

Continue reading BioBee USA and Hort Americas partner to bring growers biologically-based IPM

(Español abajo.)

Urban grower Karla Garcia is proud to announce the creation of her new company, Microgreens FLN based in Sonora, Mexico. Karla is a recent graduate with honors and a master’s degree in plant science from the University of Arizona. She is proud of her company’s commitment specializing in microgreens production using an indoor vertical farming strategy. Microgreens are an emerging class of specialty leafy greens and herbs. The crops are harvested when the cotyledons are fully developed and in some cases when the young plants have one true leaf.

Continue reading Growing microgreens with LED grow lights in Sonora, Mexico

Hort Americas has retrofitted a 12,000-square-foot greenhouse in Dallas, Texas, for the purpose of studying edible crop production in a variety of hydroponic production systems. The greenhouse is also being used to demonstrate products offered in the company’s online catalog.

Tyler Baras, who is the company’s special projects manager, is overseeing the trialing of conventional and organic substrates in different production systems.

“The trials I am focusing on are organic substrates vs. conventional substrates,” Baras said. “I’m primarily using stonewool or rockwool as the conventional propagation substrate. I am also starting to trial some loose substrates, including peat and perlite.

“The seedlings are never moved into another substrate. The seed is sown into plugs and then the rooted seedlings are moved into a deep water culture, NFT (nutrient film technique), or vertical tower production system. The plugs are really only useful for the first two weeks in propagation. Then it is really about getting the roots to grow outside the plugs so the roots grow directly in the water.”

For the organic production systems, Baras is working primarily with expandable coco plugs. He has also started working with some organic loose substrates including coco peat and perlite.

For the substrate studies Baras is working with two standard hydroponic crops, basil and lettuce, primarily butterhead lettuce.

“When I’m testing the lettuce I use either raw or pelleted seed,” he said. “With basil it’s all raw seed. Basil tends to germinate relatively easily, whether the seed is planted into a dibbled hole or sown on top of the substrate.”

A primary objective of the substrate trials is to determine the best irrigation strategies for both organic and conventional substrates.

“This is probably more important with some of the organic substrates than the conventional substrates because the organic substrates tend to hold more water,” Baras said. “One of the big challenges that organic hydroponic growers run into is overwatering their plugs because coco holds more water than conventional substrate plugs that growers are used to. Coco plugs hold more water than stonewool, phenolic foam and polymer-based peat plugs. These other plugs dry out faster than coco plugs.”

Baras said growers who are moving from conventional to organic production tend to use the same irrigation techniques they employed with their conventional propagation program.

“The growers will continue to irrigate the plugs a couple times per day,” he said. “With a lot of the organic plugs, when the seed is sown, they only need to be irrigated once every three days. If the plugs are overirrigated the roots don’t have an incentive to search out the water when they are planted into the production system. The search for water is what drives the seedling roots down to the bottom and out of the plugs.

“The goal of planting into plugs is to have the seedling roots grow outside of the plugs into the water of the deep water culture or NFT system. If the plugs are overwatered as young seedlings, the roots don’t make it down to the bottom of the plugs so it takes longer to start the seedlings and sometimes they just end up rotting because the plugs remain too wet.”

In addition to looking at the irrigation frequency of plugs during propagation, Baras is studying the impact of different methods of irrigation during propagation, including overhead and subirrigation.

“When deciding whether to use overhead or subirrigation, it depends on whether raw or pelleted seed is being sown,” he said. “If pelleted seed is going to be used, a lot of times it’s advantageous to use overhead irrigation because it helps to dissolve the coating surrounding the seed. This helps to ensure the seed has better contact with the substrate. Sometimes it’s almost a little easier to get good germination with subirrigation if raw seed is used because of the direct contact with the substrate.

“Smaller indoor growers often use subirrigation for germination. A lot of the large growers, especially those coming from the ornamental plant side such as bedding plants, usually have overhead irrigation systems installed. These growers have propagation areas set up with overhead irrigation, which can be used to start their hydroponic vegetable crops.”

Baras said most indoor warehouse growers are not going to be using watering wands or overhead irrigation in their operations.

“Most of the warehouse growers will be using subirrigation, such as flood tables,” he said. “For them it is going to be important that they select the right kind of seed to get good germination. They may have to try other techniques like using a deeper dibble or covering the seed with some kind of loose organic substrate such as perlite or vermiculite. Growers using overhead irrigation can usually sow pelleted seed without having to dibble the substrate.

“Many growers tend to have issues when they are using pelleted bibb lettuce seed with subirrigation. We are looking at ways of increasing the germination rate using dibbling with the pelleted seed or increasing the dibble size or covering the seed.”

Baras said growers who are using automation, including mechanized seeders and dibblers, prefer to use pelleted seed.

“With pelleted seed it’s easier to be more precise so that there is only one seed planted per plug cell,” he said. “I have seen automation used with raw basil seed. I have also seen organic production done where automation was used just to dibble the plug trays. Dibbling seems to be one of the biggest factors when it comes to getting good even germination.

Baras said occasionally with tightly packed coco plugs, if the seed is not pushed down into the plug the emerging radicle may have issues penetrating the substrate.

“This helps push the radicle down so it contacts the substrate and establishes more easily,” he said. “When subirrigation is used it can be advantageous to cover the seed with vermiculite or just brush the top of the coco plug after the seed is planted to get some coverage of the seed.

“What usually affects the way that coco plugs work is the size of the coco particles. There is really fine coco. There is coco fiber, which can be mixed into the plug to help with aeration and increase drainage. We are looking at various plugs with some increased fiber content trying to aerate the plugs in order to speed up the drainage.”

Baras is also looking at using loose substrates in different ratios in plugs and then transplanting them into deep water culture, NFT, and vertical tower systems.

“One of the issues with hydroponic systems and loose substrates is these substrates can enter the production system and clog up the irrigation lines,” he said. “The trick is trying to avoid having any loose substrate enter the system. We are looking at using loose substrates and allowing the seedlings to establish longer in the plug cell during propagation before transplanting them into the production system. This enables the seedlings to develop a larger root system, which can prevent loose substrate from falling into the system.”

For more: Hort Americas, (469) 532-2383; https://hortamericas.com.

David Kuack is a freelance technical writer in Fort Worth, Texas; dkuack@gmail.com.

Smart app signals new era in Precision Growing for GRODAN customers

ROERMOND, the Netherlands, − GRODAN, a global leader in stone wool substrate solutions introduces e-Gro: an easy to use, mobile app that gives real-time substrate information. e-Gro is a new service from GRODAN developed to support customers with a GroSens® MultiSensor system. Customers who need to have real-time reporting on their substrate, now have the opportunity to link their GroSens system to the e-Gro app. This new mobile and desktop application provides growers the possibility to get the maximum out of their substrate. It’s easy to use and very accurate. e-Gro is the perfect platform for professional growers interested in expanding their possibilities and keeping control of their growing in real-time. Making Precision Growing accessible from anywhere.

With the introduction of the GroSens MultiSensor system in 2013, GRODAN took the first step to enable Precision Growing by offering a tool that gave professional growers highly accurate and reliable insights into the root zone. “With technology continuously playing a more important role, we recognized the need to add a new, smart dimension to the system to service our customers 24/7 anywhere in the world regarding their irrigation strategy” explains Hub Janssen, Managing Director at GRODAN. “With e-Gro, root zone management is no longer a one-way-traffic activity, it becomes individual, easy to access and intelligent. And this is only the beginning, as we will continuously expand features and functionalities of the app over time. e-Gro is a great new service for our customers”.

What are the benefits of e-Gro?

e-Gro is available in combination with GRODAN slabs and the GroSens MultiSensor system. The app can be downloaded for free and is available in the Google Play (Android) and App Store (iOS) and can be accessed via smartphone, tablet or desktop. To find out more about e-Gro, visit www.grodan.com/e-gro

About the GRODAN Group

The GRODAN Group supplies innovative, sustainable stone wool substrate solutions for the professional horticultural sector based on Precision Growing principles. These solutions are used in the cultivation of vegetables and flowers, such as tomatoes, cucumbers, sweet peppers, aubergines, roses and gerberas. The Group offers stone wool substrates together with tailor-made advice and tools to support Precision Growing, facilitating the sustainable production of healthy, safe, and tasty fresh produce for consumers. Sustainability plays a prominent role at GRODAN, from the production of stone wool substrates to end-of-life solutions.

The GRODAN Group supplies innovative, sustainable stone wool substrate solutions for the professional horticultural sector based on Precision Growing principles. These solutions are used in the cultivation of vegetables and flowers, such as tomatoes, cucumbers, sweet peppers, aubergines, roses and gerberas. The Group offers stone wool substrates together with tailor-made advice and tools to support Precision Growing, facilitating the sustainable production of healthy, safe, and tasty fresh produce for consumers. Sustainability plays a prominent role at GRODAN, from the production of stone wool substrates to end-of-life solutions.

Founded in 1969, the GRODAN Group is active in more than sixty countries worldwide. The Group’s head office is in Roermond, the Netherlands.

For more information and images:

Stefanie Wienhoven, Corporate Communications Manager

Tel: + 31 (0) 475 – 353481

email: stefanie.wienhoven@grodan.com

If you missed the e-GRO webinar “Managing Nutrient Solutions for Hydroponic Leafy Greens and Herbs” on Jan. 22, 2016, which was sponsored by Hort Americas, you can still view the webinar on YouTube.

Hydroponic greens and herbs are produced in systems with recirculating nutrient solutions. In order to maintain productive and quality crops, it is important to know how to properly maintain the nutrient solutions. Dr. Chris Currey at Iowa State University and Dr. Neil Mattson at Cornell University discuss strategies for managing pH and EC, formulating nutrient solutions and identifying common nutrient disorders.

Part 1: Common production systems, pH and EC management

Presented by Dr. Chris Currey, Iowa State University

Part 2: Nutrient solution recipes, common nutrient disorders

Present by Dr. Neil Mattson, Cornell University

U.S. university floriculture professors and extension

specialists have collaborated to bring the floriculture industry an extensive

and thorough information resource.

|

| The American Society for Horticultural Science presented the developers of the e-GRO website with its Extension Educational Materials Award |

The two-year-old e-GRO: Electronic Grower Resources

Online website was the brainchild of Brian Krug, extension greenhouse and

horticulture specialist at University of New Hampshire, Brian Whipker, extension

floriculture specialist at North Carolina State University, Roberto Lopez,

floriculture extension specialist at Purdue University, and Nora Catlin, floriculture

specialist at Cornell Cooperative Extension of Suffolk County.

Krug said that although there is a tentative schedule as

to what is going to be written about during a specific week, the topic and

author can change depending on what growers may be dealing with. The

newsletters cover a variety of grower-related issues including disease and pest

management and environmental, physiological and nutritional disorders being

observed in commercial greenhouses.

Another part of the website is e-GRO University. This

section was developed by Krug, Whipker, Lopez, Kansas State University

floriculture professor Kim Williams, Kansas State ornamental and horticultural entomologist

Ray Cloyd and Cornell University senior extension associate and plant

pathologist Margery Daughtrey. e-GRO University is the second phase of the

website which includes over 60 videos that cover the basics of greenhouse

production. The videos are divided up into five different sections: greenhouse

management, nutrition management, growth management, insects and mites, and diseases.

e-GRO University has been funded by the Gloeckner Foundation for two years.

|

| e-GRO University provides a Greenhouse 101 curriculum that covers basic information for greenhouse management and production. |

“For e-GRO University we developed a Greenhouse 101

curriculum that provides basic information for greenhouse management and

production,” Krug said. “It is information that would be comparable to a

freshmen and sophomore college course program. Our goal was to provide an

educational resource for people who work in the industry who didn’t receive a

formal education in greenhouse production. If you are grower in a greenhouse without

the formal training or education, this program allows a person to get a handle

on some of the basics on nutrition, insects and diseases. A person can choose

to listen to any of the videos, which run 20 minutes or less. Most of the

information is basic concepts so it is not going to be changing.”

Other resources available to visitors of the e-GRO

website include:

2. e-GRO Volume One: Poinsettia

3. e-GRO Alert Volume Two

4. e-GRO Volume Three: Primula

5. e-GRO Alert Volume Four: Sclerotinia

For more:

Brian Krug, (603) 862-0155; brian.krug@unh.edu.

Visit our corporate website at https://hortamericas.com

You must be logged in to post a comment.