Have you ever noticed the different presentations of iron when selecting ingredients to make nutrient recipes?

Continue reading Iron in Hydroponic Systems

Have you ever noticed the different presentations of iron when selecting ingredients to make nutrient recipes?

Continue reading Iron in Hydroponic Systems

Fertilizer management and plant nutrition are key aspects that need to be learned when working with hydroponic systems.

Continue reading Free Download: Fertilizer Management and Plant Nutrition Guide

Organic hydroponics is possible! We can implement organic practices for hydroponic systems by using nutrient solutions derived from organic plant and animal material or naturally mined compounds. In order to certify the organic origin for a product you must look for OMRI-listed products. The Organic Materials Review Institute (OMRI) is a private, nonprofit organization that determines whether or not a product qualifies as organic under the USDA’s National Organic Program.

Continue reading Pre-Empt: An organic hydroponic fertilizer

By Karla Garcia, Hort Americas Technical Services

Plant nutrition is a key factor in growth and yield. But how can we know which nutrient is missing? Or which is the best fertilizer for our crop?

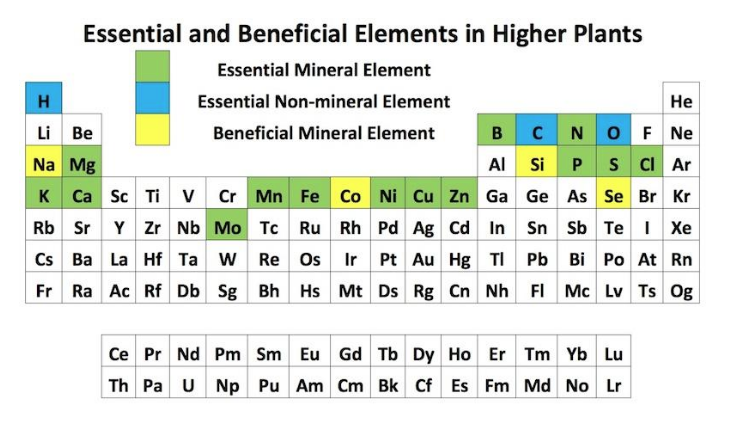

In learning about plant nutrition, we first need to know there are nutrients required in greater quantities than others. The nutrients that are essential for plant growth are called “macronutrients”. The rest of the nutrients also essential for plant growth but in lower quantities are called “micronutrients”.

Continue reading The importance of knowing basics of plant nutrition

By Deidre Hughes

Mixing your own fertilizer solutions might seem like a daunting task at first. But once you understand some fertilizer basics you’ll realize it’s not that hard to do. One of the biggest benefits of mixing your own fertilizer solutions is the amount of money you’ll save. Another benefit of mixing your own solutions from dry fertilizers is that it requires less storage space than pre-mixed fertilizers which are often in liquid form.

Continue reading Considering mixing your own fertilizer solutions?

Basil is one of the most popular culinary herbs. Whether grown as a potted crop or for fresh cut sales, basil is an herb that’s in demand year-round. Growers looking to add edibles to their product mix should consider basil to be a must-have herb in their product offerings.

Continue reading Do you want to sell the freshest, most flavorful and fragrant cut basil?

The 17 Essential Plant Elements include nitrogen, phosphorus, potassium, calcium, magnesium, sulfur, boron, chlorine, iron, manganese, zinc, copper, molybdenum, and nickel.

Continue reading Essential Plant ElementsContinue reading What are the optimum nutrient levels for hydroponic edible crops?

By Victor Loaiza, on behalf of Hort Americas

Continue reading Nutrient guidelines for hydroponic tomato production

Bell peppers grown in greenhouse hydroponic systems follow similar environmental requirements as tomatoes and eggplants. It is a common production practice to leave all the leaves on the pepper plants. This creates very tall walls of foliage that slightly affect the plants’ nutritional requirements.

Continue reading Nutrient recipe for hydroponic greenhouse bell peppers

Continue reading Are you maintaining the proper oxygen levels in your hydroponic production system?

Continue reading Organic vs. traditional hydroponic production: the top 3 differences

Hort Americas has retrofitted a 12,000-square-foot greenhouse in Dallas, Texas, for the purpose of studying edible crop production in a variety of hydroponic production systems. The greenhouse is also being used to demonstrate products offered in the company’s online catalog.

Tyler Baras, who is the company’s special projects manager, is overseeing the trialing of leafy greens and herbs in five different production systems.

“We’ve got a deep water culture or raft system using Hort Americas’ fertilizer blend with calcium nitrate and magnesium sulfate,” Baras said. “We are using that same nutrient mix in a nutrient film technique (NFT) system and a capillary mat system.

“I’m using Terra Genesis organic fertilizer in a vertical grow tower. I’m also using the same organic fertilizer for all of the seedling propagation in a flood-and-drain vertical rack.”

Photos courtesy of Tyler Baras, Hort Americas

Baras said the fertilizer recipe he is using in the deep water culture and NFT systems is based on general recommendations from Cornell University and the University of Arizona for leafy greens crop production.

The deep water culture system has been running for three months. The water reservoir for the system is 8,000 gallons.

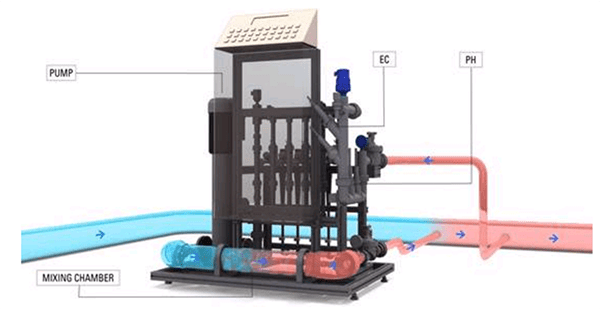

“Even if water evaporates, since it is such a large body of water, the electrical conductivity (EC) doesn’t really move much,” Baras said. “The EC has been very stable during the three months it has been operating. The reading has barely moved.”

The first trial with the NFT system, which has a reservoir of about 140 gallons, lasted for three months.

“Every week I added an additional 40 gallons of water on average to the NFT reservoir,” Baras said. “The water is evaporating and the salts are accumulating a lot faster in the NFT reservoir than in the deep water culture system. Because the NFT system has a smaller water reservoir, the quicker evaporation rate and the water replacement in the reservoir, has caused the EC to shift a lot more.”

Baras said even with the changes in nutrient levels all of the plants have been performing well.

“I haven’t seen any nutrient deficiencies or toxicities even as the fertilizer recipe has shifted over time. We have been trialing a wide range of crops, including butterhead and romaine lettuces, kale, spring mixes and basil. I’m trialing a lot of crops to figure out when these crops start to be impacted by possibly too much salt accumulation. I haven’t seen anything yet that is alarming.

“One of the things that I have seen over the years working with fertilizers is how wide the acceptable range is for plants to grow well. Between the NFT and deep water culture, the NFT is using half the nitrogen and the plants are performing very similarly. There are recommendations for EC, but none of these fertilizer levels are set. I have some systems that have 20 parts per million phosphorus and some that have 50 ppm and the plants look the same. Most general recommendations say 40-50 ppm. I’ll have some solutions that have 3 ppm iron and others that have 6 ppm iron. It is interesting to see how wide the range is for a lot of these nutrients and the crops are performing the same.”

Baras said he has seen a slowing of plant growth in the NFT system.

“I’m not seeing any deficiencies or toxicities, but the crops have slowed down about a week over the deep water culture,” he said. “Depending on the crop, it’s taking a week longer to reach either the plants’ salable weight or height.

“The slowing in growth could be related to the nutrients. This could be useful information for growers. If they are checking the EC, which may have been 2.3 when a crop was started, if there is a slowing of growth, growers may want to have a water test done. The test could show that the amount of nutrients might be changing.”

During the three months that Baras had been running the NFT system he never flushed the system.

“All that I’ve done with the NFT system is add water and additional fertilizer to maintain a targeted EC,” he said. “One of the goals of the trials is to see what ions are accumulating in the system and to see how long I can run the system before it has to be flushed. When I started the target EC was 2.2-2.3. I still achieved the target EC at three months, but the composition of what was actually in the water changed.

“Originally the NFT fertilizer solution contained about 185 parts per million nitrogen. At the end of the trial the EC was the same but there was only 108 ppm nitrogen in the solution. The calcium concentration was originally 250 ppm and ended at 338 ppm. Sulphur was originally at 80 ppm and rose to 250 ppm. Nutrients have accumulated as the water evaporated. Solely going by the EC meter reading doesn’t tell the full story of what is in that water. The EC of the fertilizer solution that I started with is the same as the EC for the fertilizer solution three months later. The difference is the ions that are making up that ending EC.”

Baras is growing a variety of cut herbs in vertical grow towers. The plants are fertilized with Terra Genesis, a molasses-based organic fertilizer. He said Hort Americas has been hearing from tower growers who are interested in trying to grow organically.

“What we are seeing is the organic fertilizer solution can change a lot over time,” he said. “The fertilizer tank solution matures as time goes on. With the organic fertilizer, the nutrients tend to balance out as the solution is run longer.

“Our city water contains calcium and some magnesium. These elements are actually the nutrients that the organic fertilizer is slightly low in. So as I run the system longer, through the addition of city water, I actually start to see an accumulation of both calcium and magnesium, which actually helps balance out the total fertilizer recipe. The balance of the nutrients has improved over time.

The pH was fairly unstable as it seemed to be going through several biological waves. It was moving rapidly between high and low. As I run the tank solution longer the total alkalinity has increased, which has stabilized it. The biological activity has also started to stabilize. The pH has stabilized in the upper 5 range. For the plants grown organically I have seen deficiencies pop up. The deficiencies were reduced as the fertilizer tank solution ran longer. The deficiencies appear to have balanced out.”

Baras said one noticeable difference between the NFT, deep water and vertical grow towers is how much slower the plants grow in the towers.

“I don’t know what to contribute the slower growth to yet,” he said. “It could be trying to determine the best fertilizer rate for the fertilizer. It could be the crop selection, because most of the crops in the towers are different from what I’m growing in the NFT and deep water culture.

“I’m going to start a deep water culture and NFT trial using organic fertilizer. I’ll have three different organic production systems running simultaneously so I will be able to compare the plant growth in each system. I’ll also be able to compare the growth of the same crops grown with organic or conventional fertilizers.”

Baras said one of the issues that can arise with using organic fertilizer is the development of biofilm in the irrigation lines that can cause emitters to clog.

“I am incorporating a product called TerraBella, which contains beneficial microbes,” he said. “These microbes help mobilize certain nutrients, like phosphorus, which can promote the formation of biofilms. This biofilm buildup is usually more of a problem with high water temperatures.

“About every six weeks I add a booster application of the beneficial microbes depending on the production system. The deep water culture system has a larger reservoir so I am not replacing evaporated water as often. For the other productions systems, like the NFT and grow towers, where I am replacing the water, I am incorporating the beneficials more often. For these systems, the fresh city water that is added dilutes the fertilizer solution. Also, there is chlorine in the city water that possibly could negatively impact some of the beneficial microbes.

For more: Hort Americas, (469) 532-2383; https://hortamericas.com.

David Kuack is a freelance technical writer in Fort Worth, Texas; dkuack@gmail.com.

Proudly brought to the commercial hydroponic and organic grower by Hort Americas and specifically developed for recirculating nutrient film technique (NFT), the Pre-Empt Hydroponic Nutrient is packed with the essential micro- and macro-nutrients, amino acids and vitamins plants hunger for!

Pre-Empt goes through a five stage fermentation process which is above and beyond other products by incorporating molasses with other natural plant extracts. This process packs Pre-Empt with essential macro-nutrients, micro-nutrients, amino acids like humic and fulvic acid, as well as an array of vitamins which build a full spectrum of nutrients that plants desire.

Excellent for lettuces, basil, leafy greens and culinary herbs

OMRI-listed

We suggest pairing with Terra Bella to naturally promote the uptake of nitrogen and other essential nutrients for plant health. The combination of aerobic and anaerobic microbes works throughout the root zone to increase crop yield and resistance to disease and pests.

For further resources including a quick video and Organic Fertilizer Programs, click here!

Pre-Empt can be used in conjunction with a solution grade organic gypsum (calcium sulfate) and magnesium sulfate.

Hort Americas is an innovative leader in North America’s controlled environment agriculture industry (CEA) and strives to continually innovate in agriculture via premium technical support, professional salesmanship, unmatched customer service and outstanding products to our customers in the United States, Canada, Mexico, and the Caribbean.

For questions and support, click here!

If you missed the e-GRO webinar “Managing Nutrient Solutions for Hydroponic Leafy Greens and Herbs” on Jan. 22, 2016, which was sponsored by Hort Americas, you can still view the webinar on YouTube.

Hydroponic greens and herbs are produced in systems with recirculating nutrient solutions. In order to maintain productive and quality crops, it is important to know how to properly maintain the nutrient solutions. Dr. Chris Currey at Iowa State University and Dr. Neil Mattson at Cornell University discuss strategies for managing pH and EC, formulating nutrient solutions and identifying common nutrient disorders.

Part 1: Common production systems, pH and EC management

Presented by Dr. Chris Currey, Iowa State University

Part 2: Nutrient solution recipes, common nutrient disorders

Present by Dr. Neil Mattson, Cornell University

You may also want to

visit the Water Education Alliance for Horticulture. The Water Education Alliance for Horticulture is a team

of researchers and industry experts led by the University of Florida. Their mission is to “help growers conserve

irrigation water and manage water quality issues.”

Visit our corporate website at https://hortamericas.com

The University of Florida has produced a series of online

educational videos called Virtual Field

Day (http://vfd.ifas.ufl.edu/). The videos present information on a variety

of topics (hydroponic production systems, soilless media, nutrient solution

delivery, pest management, harvesting and marketing) with visual support

including instructional how-tos. One of videos was made by associate professor

Danielle Treadwell who discusses the use

of organic fertilizers (http://virtualfieldday.ifas.ufl.edu/gainesville/organic_produce/selecting_fertility_media.shtml)

in greenhouse vegetable production.Visit our corporate website at https://hortamericas.com

Its finally up and live! Kimitec.com is the perfect place to go to learn about the latest trials on this organic and non-organic line of fertilizers. From Amifort to Tundamix, the Kimitec Group (along with the support of American Clay Works in North America) continue to focus increased yield, plant health and vigor. Please follow this link to learn more about Kimitec Trials in hydroponics, commercial greenhouses and general agriculture.

Visit Hort Americas for additional technical information and to buy your Kimitec today.

Visit our corporate website at https://hortamericas.com

You must be logged in to post a comment.