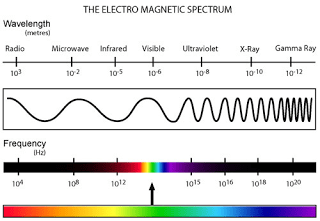

Introduction: The Light Emitting Diode, commonly referred to as the LED, is probably something you have heard or read about by now. LEDs can be found in everything from automobile head lights and tail lights, traffic lights, handheld flashlights and so on. LEDs are even being tested as a wireless LAN alternative. Simply put, LEDs are showing up everywhere. An LED is more like that of a computer chip than a light “bulb”. That’s because it is a solid-state semiconductor device. In 2008, LEDs occupied 7% of global lighting market share. In 2010, 20% of the global lighting market share was with LEDs. By 2020, LEDs are estimated to occupy 75% of global lighting. Although LEDs may seem to be a relatively new light source they were actually invented in the 1920’s. However, a visible light (380 nm to 780 nm, Fig. 1) version was not developed until the early 1960’s. That first visible light version was red in color and additional wavelengths (green, yellow, and orange) were developed through the 1970’s. In 1993, the first blue LED was developed. With the addition of a phosphor coating to the blue LED, the white LED was created. The color of light emitted by any LED is determined by the type of semiconductor material and the impurities used to form the LED. Although safe, caution should be used when using UV-B and UV-C LEDs. At sufficient levels UV-B and UV-C wavelengths can be dangerous to the human eye and skin. Additionally, some LEDs are bright enough to cause eye damage and should not be looked at directly. LEDs offer many positive characteristics over traditional lighting sources.

Advantages/Challenges: The two most commonly discussed advantages to using LEDs are efficiency and lifetime. LEDs are more efficient (output divided input) than incandescent and fluorescent lamps and are essentially equivalent to high-intensity discharge (HID) lamps. White LEDS are less efficient because the phosphor coating must interact with the base color (usually blue) to create white light. There exists potential for significant cost savings of LEDs over other current horticultural lamps. Unlike traditional lamps, LEDS generally do not “burn out”. The metric used is the LED’s “lifetime” which is the time (in hours) required for the light output to drop below a percentage of the original maximum intensity under optimal operating conditions. Generally speaking, growers will replace their lamps when the light output drops below 90%. Therefore, a grower can expect a lifetime of approximately 25,000 hours at 90%. The long operational life of LEDs nearly eliminates the procurement and disposal costs for replacement bulbs. Associated labor cost would also decrease. LEDs emit little or no radiant heat. However, there is a loss of heat from the diode junction. The thermal output can be significant when LEDs are used in high-densities. LEDs also offer the advantage of turning on instantly and do not require warm-up time. They also turn off instantly. One subtle, yet important, advantage to LEDs is that they do not contain hazardous materials unlike fluorescent lamps which contain mercury and require special disposal. LEDs also do not produce damaging ultraviolet wavelengths, (unless using UV LEDs), as do HID lamps if the protective envelop breaks. Due to their size, LEDs offer flexibility in fixture design. The primary difficulty which has prevented mass LED installations for greenhouse lighting has been cost. Although the initial cost may be higher than other supplemental light sources, the ROI is much shorter due to energy efficiency and life span. Secondly, the cost of LEDs is constantly decreasing and companies like Philips Lighting and others are offering affordable LED technology. The primary technical obstacle to using LEDs for horticulture lighting is the low light output of some current LEDs wavebands of interest to horticulturists. Although an LED replacement to today’s HID lamp does not exist, sources estimate that one will be available in 3 to 5 years. Nevertheless, LED modules of desirable wavebands exist and are currently being used for multilayer production and intracanopy lighting (Fig. 2 and 3, respectively). Other LED lamps being produced have a standard E27 fitting, which allows for direct replacement in existing installations. No additional modifications are required (Fig. 4).

Horticulture Applications: The ability to control spectral quality is of interest for crop production and is not easily achieved with broad-spectrum light sources. LEDs produce narrow-spectrum wavelengths they have been manufactured in highly plant-absorbed colors. Spectra can be customized and even modified to match the crop needs and control the photoperiod or growth cycle. Therefore, LEDs require a systematic approach which is dependent on the crop being grown and the goals of the grower. Since growers are using highly plant-absorbed colors, LEDs should produce much less wasted light and energy versus using non-productive wavelengths. Recall that LEDs emit very little if any radiant heat which allows them to be operated close to the canopy. This also increases the light intercepted by the plant further improving the use efficiency. The capability of using LEDs closer to the plant canopy provides options such as multilayer production of many crops including tissue culture. Multilayer production using other light sources is possible. However, more shelves per unit volume are possible with LEDs. For example, one grower decreased their light energy consumption by more than 50% and increased their multilayer production by 33% without additional production volume simply by switching to LEDs.

Summary: LEDs possess several characteristics that make them an attractive greenhouse supplemental light source. Control over the spectral composition is possible with LEDs. They provide high light output with low radiant heat. Their small size offers flexibility in design and placement. Last, but not least, they are exceptionally long lasting and are more energy efficient than other supplemental light sources. The outlook for solid-state lighting technology is bright (pun intended). LEDs are a prime candidate for use in controlled environment agriculture. They are another tool available to extend production seasons, increase yield, and improve quality. One final mention is the light output unit of measurement. You will not report in footcandles with LEDs. Their output is reported in micromoles per square meter second (µmol·m-2·s-1). We will cover horticultural lighting basics in an upcoming newsletter article, so stay tuned. In the meantime, if you have additional questions regarding LED lighting please contact Hort Americas, LLC. We appreciate your interest and look forward to working with you soon. Make it a Great Day!

|

|

Figure 1. The Electro Magnetic Spectrum. Visible light is considered to be between 380 nm to 780 nm.

|

|

|

Figure 2. Image of LED modules being used in multilayer production. Photo courtesy of Philips Lighting (www.philips.com/horti).

|

|

|

Figure 3. Interlighting module being used in high-wire greenhouse tomato production. Photo courtesy of Philips Lighting (www.philips.com/horti).

|

|

|

Figure 4. . Philips GreenPower LED flowering lamp. Photo courtesy of Philips Lighting (www.philips.com/horti).

|